Wind Turbine Inspection & Blade Repair Specialists

ABOUT KOMPACT

RENEWABLES

Kompact Renewables provide high quality wind turbine services in the hard to access areas, specialising in repair of wind turbine rotor blades / inspection of rotor blades / tower inspection / tower repairs.

Blade Repair / Maintenance

Our experienced and professional blade repair teams are capable of everything from large structural repairs to blade maintenance on all blade manufacturers.

As a method of access our blade technicians are trained in :

• Rope Access (IRATA) for smaller repairs and maintenance

• Blade access platforms for larger structural repairs

• MEWP Access for short hub height turbines.

Inspection

We provide a range of inspection services to fit the client’s needs.

• Rope access blade & tower inspection.

• Drone inspection

• Ground based camera inspection

High quality inspection reports are generated and provided to the client with the inspection findings clear to see

Tower repairs / Maintenance

We have technicians experienced in all aspects of tower repairs

• Tower paint repairs (spot metal)

• Tower sealing

• Concrete tower repairs

• Bolt torquing

Wind Turbine Services

Blade Repair / Maintenance

Blade Access Platform

Kompact Renewables use Blade Access platforms for large structural repairs and large blade maintenance scopes, we have access to many different types of blade access platform through our partners in the wind industry suitable to fit any turbine type/height.

Our technicians are experienced in multiple blade platform types and experience rigging on a wide variety of turbine types.

Advantages of Blade Access Platform:

• Working space – More space for equipment and materials ideal for large repairs

• Stability – Platform is touching the blade with a blade wheel, this means both the blade and tower move together with wind forces, this makes it a lot easier for complex grinding work.

• Habitat – Some of our platform types have built in weather habitats allowing our technicians to control conditions inside to minimise downtime.

Blade Access Platform

Kompact Renewables use Blade Access platforms for large structural repairs and large blade maintenance scopes, we have access to many different types of blade access platform through our partners in the wind industry suitable to fit any turbine type/height.

Our technicians are experienced in multiple blade platform types and experience rigging on a wide variety of turbine types.

Advantages of Blade Access Platform:

• Working space – More space for equipment and materials ideal for large repairs

• Stability – Platform is touching the blade with a blade wheel, this means both the blade and tower move together with wind forces, this makes it a lot easier for complex grinding work.

• Habitat – Some of our platform types have built in weather habitats allowing our technicians to control conditions inside to minimise downtime.

Rope Access

Our IRATA trained technicians have competency to use rope access methods to access the blade. Rope Access teams will always have at least 1 IRATA Level 3 in charge of the overall safety on site. We use power ascenders to access the blade from ground level taking tools and materials up to the working area in approved lifting bags.

Advantages of Rope Access Method:

• Fast – Set up & de rig

• Can carry out small / medium sized repairs

• Access from the top (nacelle) or ground (Using power ascender)

MEWP Access

For shorter Hub height turbines MEWP access can be the most efficient way to carry out repairs. Our technician will receive on-site training provided by our Plant rental partners, Each training is specific to the type of MEWP. As a rough estimate, wind turbines above 70m hub height it is not cost effective to use MEWPS as a method of access.

Advantages of MEWP Access:

• Fast – Set up & de rig (Technicians only need to lock the rotor)

• Technicians can perform Medium / Large repairs from MEWP

• Fast method for maintaining LE erosion

Ground

It is very common for wind turbine blade to be damaged during transport. Our blade teams mobilse to site and make repairs before the damaged blade is installed. This method is much more cost effective than installing damaged blades and repairing afterwards. We can arrange that weather habitats are built around the working area so there is no down time even in winter conditions.

Advantages of ground-based repairs:

• No repairs needed after blade is installed

• No down time if weather habitat used.

• Scaffold can be arranged if the damaged area is unreachable from ground level

Internal

Internal blade repairs can be performed with either the blade on the ground or if the blade is installed with the rotor locked in 3 o’clock / 9 o’clock position.

Small internal blade repairs can usually be controlled with dust chambers set up in the damaged area, large repairs need an air extraction system set up and dust chambers. Our experienced blade repair teams have advanced rescue training for working inside rotor blades.

Inspection

Blade Inspections

Kompact Renewables offer a wide range of blade inspection services fitted to the clients needs. Detailed inspection reports are generated with damages and defects categorised to show the client a clear overview of the blade condition.

Method of inspections:

• Drone inspections (UAV)

• Rope access inspection for up close detailed inspection

• Ground based camera inspection

• Internal hands-on inspection (Reachable areas)

• Internal drop camera inspection (Unreachable areas)

Blade Inspections

Kompact Renewables offer a wide range of blade inspection services fitted to the clients needs. Detailed inspection reports are generated with damages and defects categorised to show the client a clear overview of the blade condition.

Method of inspections:

• Drone inspections (UAV)

• Rope access inspection for up close detailed inspection

• Ground based camera inspection

• Internal hands-on inspection (Reachable areas)

• Internal drop camera inspection (Unreachable areas)

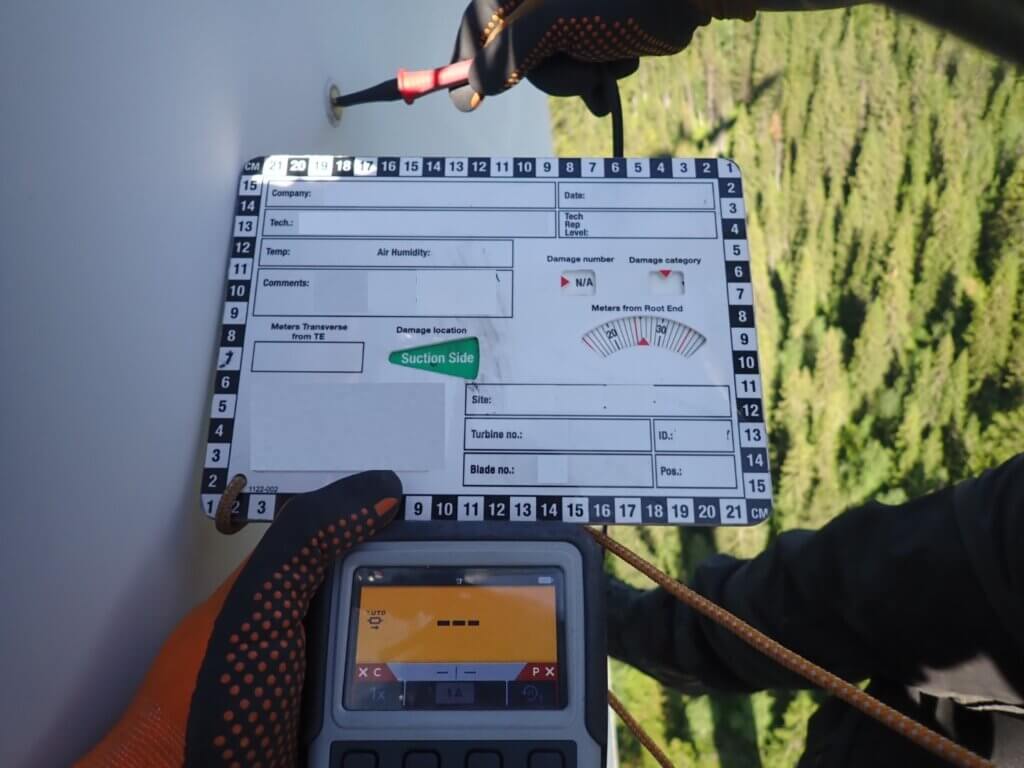

LPS Inspections

Lightning Protection Systems play a crucial role in protecting the wind turbine from unwanted damage. If a lightning strike occurs and the LPS system is not working according to the OEM’s specifications there is a high risk of large structural damage.

The LPS system directs the lightning strike through cables inside the blades and tower to the ground. With proactive testing defects can be found and repaired before any damage is caused.

Our skilled teams use Megger testing equipment to measure the insulation resistance of the LPS componentes. The Megger tester will send a voltage through the LPS component and measure the current that flows through, therefore calculating the resistance in the LPS system.

Tower Inspections

Towers are a critical part on the wind turbine system they can be made from different materials, have different designs and a variety of different heights.

It is important to detect any defects in the early stages to prevent further damage / erosion.

Our technicians can provide detailed inspection of tower components giving the client an overview of the tower condition, and recommendation of any repairs needed.

Methods of inspection:

• Drone inspections of towers

• Rope access inspection for up close detailed inspection

• Ground based camera inspection

Tower types:

• Steel

• Reinforced concrete

• Hybrid

• Potentially from Wood (New design coming soon)

Tower Repairs / Maintenance

Rope Access

Most tower repairs can be performed using rope access techniques. Our teams have experience in spot metal repairs, tower sealing, bolt torquing and installation of aviation lights. Rope Access techniques are the most efficient way to carry out tower repairs, with quick set up and derig times, minimising production downtime for the wind turbine.

Rope Access

Most tower repairs can be performed using rope access techniques. Our teams have experience in spot metal repairs, tower sealing, bolt torquing and installation of aviation lights. Rope Access techniques are the most efficient way to carry out tower repairs, with quick set up and derig times, minimising production downtime for the wind turbine.

1-2m Suspended Platform

Tower access platforms are a suitable access method for large repairs that require more equipment. Our teams have used 1-2m platforms for concrete repairs where hollow spots are identified / removed and repaired.

Contact us

Email Address

Naithan Mcinnes – Operations Director